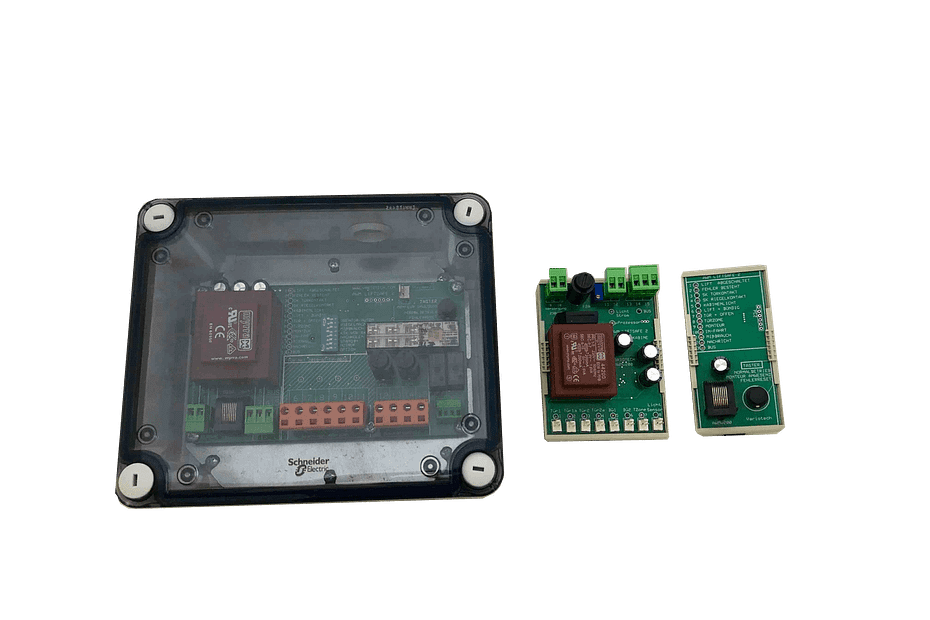

Liftsafe 2 switches off the elevator in the event of safety-related errors and reports the cause. Liftsafe also reports broken cabin lighting or if the elevator does not stop flush. Test messages can be triggered for test purposes. Detected deviations from normal operating status are saved in the emergency call center with the date, time and type of error. The status of all important modules is indicated by LEDs. A “test” message can be send without influencing the elevator. Liftsafe 2 consists of 3 modules.

Thanks to the modular system, you can conveniently monitor the status of the device in real time from the control box. 1.

Main module

Installation in the machine room or in the shaft

The main module is the central control center, where the roof control module and the display module are connected and evaluated.

Roof control module

Installation on the cabin roof

The module includes cabin light monitoring, which is carried out by means of current measurement or the supplied cabin light sensor. Furthermore it is checked if the elevator is flush. Also the correct opening of the cabin door are monitored with the help of magnetic switches. A second or third cabin door can also be connected (optional). The input to the door zone serves to protect against misuse for emergency call systems.

Display module

mounting directly in the control box (also GEARLESS).

The display module is an indicator of the elevator or elevator safe conditions such as elevator switched off, error exists, safety circuit door contact, safety circuit bolt contact, cabin light, lift flush, door open, door zone, technician present, in-travel, abuse, and message. Errors can be easily reset using the “technician present” button. In installation mode, the Liftsafe hides 2 errors that occur.

Order Codes

-

AWM-V2-2N-LIFT8for connecting to 2N-LIFT8

-

AWM-V2-LC-410Xfor connecting to DIGIFON

-

AWM-V2-MEMCOMfor connecting to MEMCOM

-

AWM-V2-SAFELINEfor connecting to SAFELINE